Scientists Discover New Lithium Battery Recycling Process

Kallipso Mais

on

September 30, 2024

Scientists Discover New Lithium Battery Recycling Process Without Heat Or Chemicals

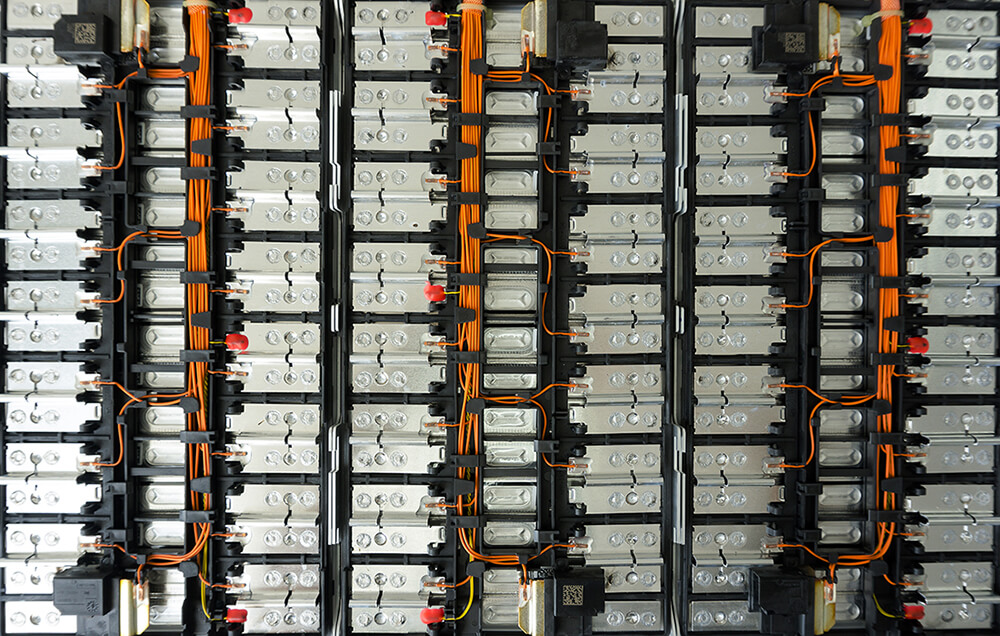

US scientists have discovered a lithium battery recycling process which does not require high heat of chemicals. Scientists from the U.S. Department of Energy’s Ames National Laboratory have said that the process requires only water and carbon dioxide. This has been named Battery Recycling and Water Splitting (BRAWS) technology.

How Does BRAWS Technology Work?

The BRAWS technology works by immersing used lithium-ion batteries in water and subjecting them to carbon dioxide. When carbon dioxide is dissolved in water, it creates a weak acid that facilitates the breakdown of the lithium-containing compounds in the battery.

This allows the valuable materials, such as lithium, cobalt, and nickel, to be extracted without the need for high-energy smelting processes or toxic chemical treatments.

The method is highly efficient, using basic chemistry principles to selectively separate and recover key components of the battery. By avoiding the harsh conditions of traditional recycling methods, this process significantly reduces the energy input and environmental impact typically associated with battery recycling.

What Are The Advantages Of This Recycling Process?

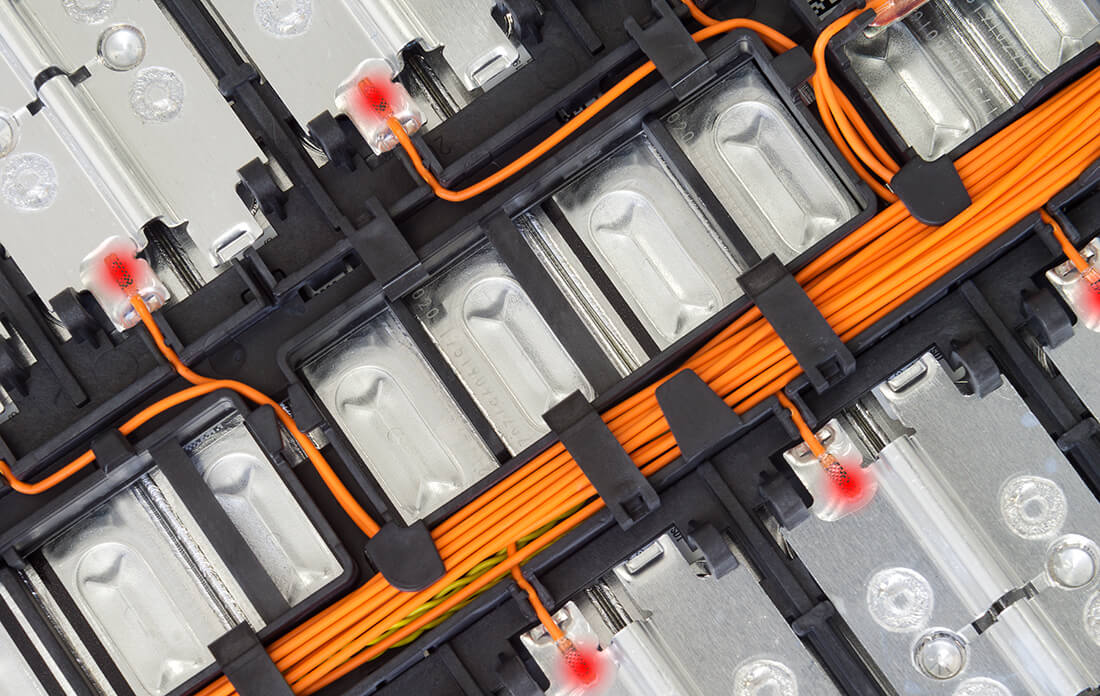

Environmental Sustainability: Unlike conventional methods, which rely on high temperatures or strong chemicals, the BRAWS process uses only water and carbon dioxide, making it a greener alternative. This reduces harmful emissions and the need for toxic chemicals that can pollute the environment.

Lower Energy Use: Traditional recycling methods often require extreme temperatures, consuming vast amounts of energy. The new process operates at room temperature, dramatically lowering the energy required to recycle batteries.

Cost-Effective: With fewer complex steps, reduced energy input, and the elimination of costly chemicals, this new method could significantly lower the cost of recycling lithium-ion batteries, making it economically viable on a larger scale.

Efficiency in Material Recovery: The process allows for a higher recovery rate of valuable materials like lithium, cobalt, and nickel, ensuring these critical minerals can be reused in new batteries, reducing the need for virgin mining.

This breakthrough is timely, as demand for lithium-ion batteries continues to rise with the increasing adoption of electric vehicles and renewable energy storage. Developing efficient and sustainable recycling processes like BRAWS is crucial to ensuring a more circular lithium economy, reducing reliance on mining, and minimising environmental impact.

We Recycle Lithium Batteries

At Lithium Cycle, we specialise in recycling lithium batteries. This includes lithium batteries used for electric vehicles, e-bikes, e-scooters, solar storage, and much more. If you are business generates bulk loads of battery waste, we can offer a safe and sustainable disposal route. Get in touch today to book a collection and ensure your waste is recycled.