Do Hybrid Cars Have Normal Batteries?

Kallipso Mais

on

October 21, 2024

Do Hybrid Cars Have Normal Batteries?

At A Glance...

- Modern hybrid cars use lithium-ion batteries and nickel-metal-hydride (NiMH) batteries.

- Li-ion batteries have a higher energy density compared to NiMH batteries.

Modern hybrid cars use lithium-ion batteries and nickel-metal-hydride (NiMH) batteries.

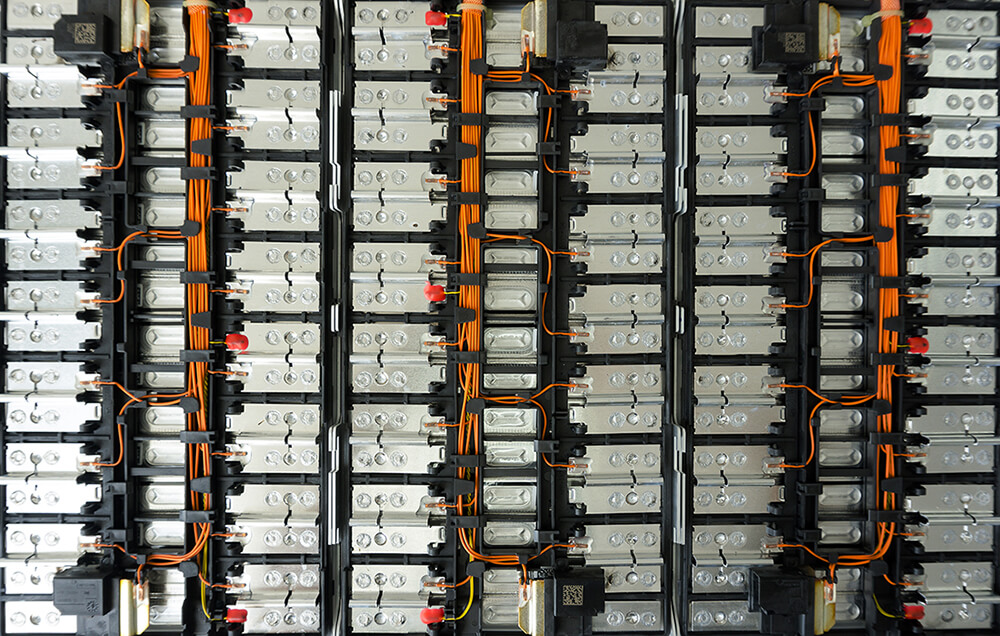

The type of battery used in a hybrid car really depends on the make and model. For instance, if you’re driving a plug-in hybrid like the Toyota Prius Prime or Chevrolet Volt, chances are you’re benefiting from a large li-ion battery pack under the hood. Why? Li-ion batteries have a higher energy density compared to NiMH batteries, which means they can store more electrical energy in a smaller, lighter package.

This allows plug-in hybrids to go further on electric power before the gasoline engine has to kick in to recharge the battery or help drive the car.

On the other hand, some hybrids, especially older models, rely on NiMH batteries. These batteries may not be as energy-dense, but they’re tough, reliable, and get the job done when it comes to powering the electric motor. They’ve been around longer, and for many hybrid cars, they’re still a solid choice.

Why Do Hybrid Cars Use These Battery Types?

Hybrid cars are all about efficiency, and these battery types—whether lithium-ion or nickel-metal-hydride—help maximise fuel economy. By storing and releasing electrical energy when needed, hybrid batteries allow the car to seamlessly switch between gasoline and electric power. This reduces fuel consumption and makes hybrids incredibly fuel efficient.

A key reason hybrids use these specific battery types is because of regenerative braking. When you brake, the car captures that wasted energy and uses it to recharge the battery, boosting your efficiency even more. It’s like magic—except it’s all science! High-voltage batteries are essential for this process, as they can store the electrical energy needed to keep things running without relying solely on gasoline.

In addition to improving efficiency, both li-ion and NiMH batteries are durable enough to handle the frequent charging and discharging cycles that come with hybrid driving. This means that while the battery may seem to be working hard in the background, it’s built to last.

How Do I Dispose Of Hybrid Vehicle Batteries?

One thing that often gets overlooked is what happens when these batteries reach the end of their life. And yes, they do eventually run out of juice—though they last longer than many people think. So, how long do hybrid batteries last? Well, it can vary depending on the make, model, and how the vehicle is driven, but many hybrid batteries are built to last anywhere from 8 to 15 years.

When the time comes to replace that trusty hybrid battery, don’t just throw it in your general rubbish. Hybrid batteries are recyclable, and that’s where we come in. If you’ve got an old li-ion from your hybrid or electric vehicle, we can collect and recycle it responsibly.

By recycling, you’re helping ensure that valuable materials are recovered and reused, and you’re keeping toxic chemicals out of landfills. Plus, it means fewer resources are needed to produce new batteries, making the entire process a little bit greener.

Remember, these batteries are high-voltage powerhouses, so handling and disposing of them properly is crucial. Always recycle through certified programs to make sure you’re doing your part in maintaining a sustainable cycle of battery production and disposal.